It's not only an ordinary hose pipe but hydraulic hose pipes are best and significant tides used in machines for transferring liquids to the destination. In this lesson we will know hydraulic hosepipe working, Components of hydraulic hosepipe, selecting the correct hydraulic hosepipe, maintaining the hydraulic hosepipe, and troubleshooting the hydraulic hosepipe.

Hydraulic hose pipes are essentially specialty specific pipes that are responsible for transferring liquids with great pressure and force from one place to another. These pipes are constructed of durable materials such as rubber and metal. Rather, this solid structure ensures the fluid remains in the pipe and does not escape. Hydraulic hose pipes are used in a wide variety of machines including construction machines for buildings, cars for roads, airplanes for the sky, etc. All these machines depend on Eastop hydraulic suction hose to function and move properly.

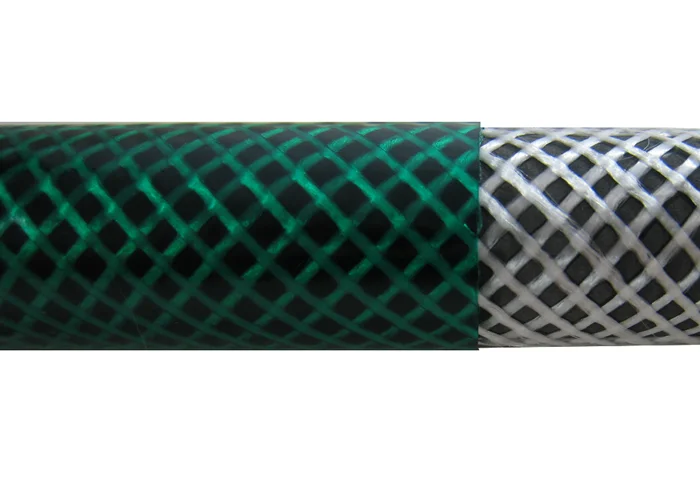

The main body of a hydraulic hose pipe consists of three main parts that function together to ensure completing its work satisfactorily. The second is the inner tube. This is a tube that the liquid flows through. The second part has a reinforcement layer. The second layer, which is also crucial, is what strengthens the pipe to withstand the pressure of the flowing liquid in there. Thirdly, the outside layer protects the pipe from physical damage, such as dings and scratches. Together, these three parts (inner tube, reinforcement layer and outer layer) are the team players ensuring that the hydraulic hose pipe performs its function without any hassles.

It is essential to carefully considered a few things when you need to choose a hydraulic hose pipe. The first factor to consider is what type/capacity of liquid the pipe will be in contact with. Other pipes may be required for other liquids. Next, consider the maximum pressure the pipe would be under. Some machines operate at extremely high pressure, and others do not. Finally, think about what temperature the pipe will face. Some pipes are better for hot conditions, while others are built for cold conditions. The choice should also depend on these factors, so that the Eastop flexible transparent pipe can do its job properly in the machine or the work you are doing.

Proper maintenance of your hydraulic hose pipe is required to ensure it has a long and successful career. That means checking the pipe regularly to see whether it’s leaking, which is to say whether any of the liquid might be escaping. You should also ensure that the connections, or the point where the Eastop wire braided rubber hose pipe connects with the machine, are tight and secure. Maintaining cleanliness of the pipe is highly significant also, as pollution and grime can create problems. Any signs of age or damage to your hydraulic hose pipe is a good reason to replace it. If you do this, you can avoid accidents and ensure the machines are operating safely for many years to come.

One of the problems that can occur with hydraulic hose pipes is the emergence of leaks or bursting. If you also see leaks, then it is crucial that you stop using it immediately. Using the machine further may exacerbate the issue. You can temporarily cover small leaks with tape or special glue. But, if the issue is large or if the pipe is broken, then it is better to completely change the hydraulic hose pipe. Eastop pvc air pipe will guarantee a smooth and secure operating of your machine.

Our facility covers 62 000 square meters and has Hydraulic hose pipe showcasing our commitment to the efficient production With over 300 production lines in operation We are able to meet the needs of our customers while ensuring high standards for quality Our 230 highly skilled workers play a vital role in ensuring our products meet our exact specifications

We are extremely proud of having earned the ISO Certificate a testament to our dedication to Hydraulic hose pipe and constant improvement in all aspects of our operations a staggering annual output of 30 000 tonnes and growing have made ourselves one of the leading supplier of hoses in China is a testament to our dedication to quality and are able to consistently provide products that meet the highest industry standards Our growth is fueled by our focus on customer satisfaction innovation and maintaining strong relationships with our customers positioning us as a trustworthy partner in the market

We have adopted the latest technology and equipment and strict control of our Hydraulic hose pipe and manufacturing process. Our products are superior in quality and we assure that they will meet the standards of Reach. Rohs, Pahs, etc. As of now, we've exported to more than 80 countries and serving more than 500 clients like United Kingdom, United States, Canada, Australia, Brazil, Colombia, Chile, Peru, Nigeria.

Hydraulic hose pipe is committed to the manufacture and exportation of plastic and rubber hoses. Our main products include PVC hoses for air, water as well as gas and oil powders, granules, etc. and hydraulic hoses. Used in agriculture, construction mining, industry, and other industries. We can satisfy the requirements of various customers.