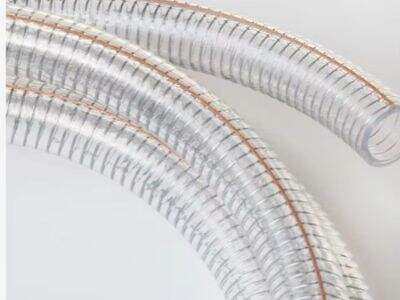

Já pensaste no que é que se passa quando falamos de pressão e vácuo nos nossos tubos transparentes? Por que você se importa com a pressão e vácuo classificações de tubos transparentes Bem, a explicação é fácil: para que o tubo suportar a quantidade adequada de pressão ou vácuo sem falha., vamos apresentar-lhe alguns fatos sobre tubos transparentes pressão e vazio classificações, formas de estabelecer uma press tubulação de pvc transparente para o seu uso particular, e também dicas sobre como manter a pressão e o vácuo para tubos transparentes.

Por que tanto respeito à pressão e ao vácuo?

Pressão e vácuo: pressão e vácuo para tubos transparentes são como os níveis de força para um super-herói. Indicam quão grande é a pressão interna ou o vácuo mangueira transparente pode tomar antes que comece a meter-se em sarilhos. Se a pressão ou o vácuo for muito alto para o tubo, ele pode estourar ou entrar em colapso, você tem uma grande confusão nas mãos. Por isso é especialmente importante conhecer as classificações de pressão e vácuo dos tubos transparentes antes de os ter em mente para um projeto.

Como calcular a pressão máxima e o vácuo para tubos transparentes

Tens de verificar as especificações para saber a pressão máxima e o vácuo. Estes seriam o código secreto do tubo: uma vez que conhecesses estes números, saberias tudo o que importava. As notas de pressão e vácuo são listadas no próprio tubo ou no manual do produto. Se não conseguir descobrir, não hesite em perguntar a um adulto ou a alguém que entenda mangueira de linha de combustível transparente .

Efeito da temperatura e do meio sobre as classificações dos tubos

Tal como acontece com alguns dos seus super-heróis favoritos em um momento de perigo, a pressão e o vácuo dos tubos transparentes podem variar dependendo da temperatura e do ambiente. Tais tubos podem ser enfraquecidos por calor excessivo com arrefecimento acompanhado, tornando-os assim mais suscetíveis a alta pressão e/ou vácuo. Outros fatores a considerar ao usar tubos transparentes em vários projetos para garantir que eles possam funcionar e durar!

Escolhendo tubos transparentes para sua aplicação

Para garantir que obtém o melhor tubo de plástico transparente para o seu trabalho, precisa saber com que líquido ou gás o tubo entrará em contato, qual é a temperatura desse líquido/gás e qual será a pressão ou a situação de vácuo para esse líquido/gás. A Eastop fornece muitos tipos de tubulações transparentes para atender às suas diferentes necessidades. Use o tubo certo e não terá acidentes.

Como obter valores de pressão e vácuo para tubos de plástico transparente

Para preservar a integridade dos tubos transparentes e garantir que nunca percam sua pressão ou vazio, é preciso ter cuidado com a forma como os tratam. Não dobre ou torça o tubo demasiado, porque se quebra. Verifique se o tubo está desgastado (fissuras ou fugas) e substitua-o conforme necessário. Os tubos transparentes podem resistir por algum tempo com TLC suficiente, com armazenamento e limpeza adequados.

Sumário

- Por que tanto respeito à pressão e ao vácuo?

- Como calcular a pressão máxima e o vácuo para tubos transparentes

- Efeito da temperatura e do meio sobre as classificações dos tubos

- Escolhendo tubos transparentes para sua aplicação

- Como obter valores de pressão e vácuo para tubos de plástico transparente

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FR

FR

DE

DE

IT

IT

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

HU

HU

TH

TH

MS

MS

BN

BN