Tubos flexíveis reforçados — um tipo adicional de tubo, uma mistura de força e flexibilidade; Eles têm muitas aplicações, mas mais notavelmente em grandes projetos de construção, para edifícios e pontes. Os tubos são fabricados com materiais muito resistentes e tolerantes à pressão. Essa resistência significa que eles duram muito, o que é vital para projetos de construção.

Os tubos flexíveis reforçados são versáteis e podem ser dobrados e torcidos, uma qualidade especial que os torna uma das principais vantagens quando utilizados durante a construção. Isso permite que sejam usados em lugares confinados onde outros tipos de tubos, como os do estilo antigo, rígidos, podem ter dificuldade. Essa versatilidade os torna incrivelmente úteis para construtores, pois podem ser implementados em uma variedade de cenários. Além disso, esses tubos são mais leves que os tubos regulares. Mais leves — isso significa tanto mais fáceis de mover quanto mais fáceis de instalar, o que pode acelerar projetos de construção.

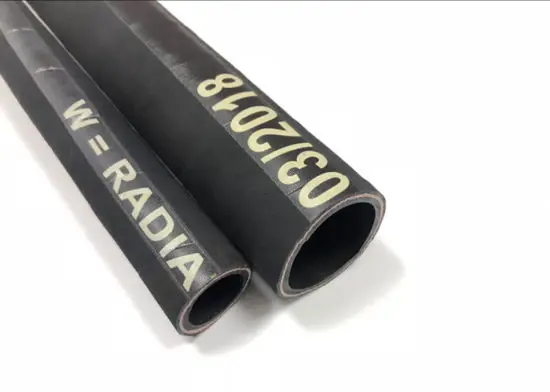

Os tubos flexíveis reforçados também são muito resistentes, o que é uma de suas características mais fortes. Durabilidade: Esses tubos são projetados para suportar anos de uso sem rachaduras ou vazamentos. Isso é particularmente crucial em trabalhos de construção, onde, como no caso dos tubos, as coisas muitas vezes ficam enterradas profundamente no subsolo ou o material deve ser capaz de suportar altas pressões. O mangueira de PVC reforçada s sendo de alta resistência e, portanto, menos propensos a falhar sob pressão. Essa confiabilidade pode, eventualmente, economizar uma quantidade significativa de tempo e dinheiro para os construtores, que não precisam substituir os tubos com tanta frequência.

As aplicações de tubos flexíveis supervisionados também estão ganhando uma tração importante no setor de óleo e gás. Estes são usados para transportar óleo e gás de um lugar para outro. Você pode ter flexibilidade para direcionar suas pernas ou dedos para outros lugares. Esses tubos são como o setor de óleo e gás move seu produto de forma segura e eficiente. Eles são duráveis e capazes de suportar alta pressão e temperatura, sendo amplamente utilizados em várias indústrias.

Investir em tubos flexíveis reforçados diversifica ainda mais o que você pode construir além de estruturas simples. Eles também são encontrados em numerosos outros campos, incluindo encanamento e irrigação. Tais tubos são muito úteis para transportar água, produtos químicos e outros líquidos, o que os torna altamente úteis em muitas indústrias. Eles conseguem se curvar e flexionar, permitindo que os trabalhadores os instalem e trabalhem com facilidade, e sua construção robusta permite que realizem trabalhos difíceis sem quebrar.

Selecionar materiais adequados para tubos flexíveis reforçados é imperativo para o seu sucesso. Cada material tem suas vantagens e desvantagens, portanto, é importante que o material certo seja escolhido para cada trabalho específico. A Eastop – uma fábrica que se concentra nesses tubos – oferece diferentes materiais, desde borracha até plástico e metal. Embora cada tipo de material venha com seus próprios benefícios, é importante entender os requisitos específicos do projeto antes de tomar uma decisão.

Finalmente, você pode conhecer a interessante ciência por trás do design de tubos flexíveis reforçados. Este ambiente em constante mudança leva engenheiros e cientistas a buscarem novos métodos para melhorar esses tubos. Eles estão tentando fazer tubos que sejam mais fortes, mais leves e mais flexíveis do que nunca. Se houver algo mais a acrescentar, é que a Eastop está na liderança nesta tecnologia e está trabalhando em novos materiais e designs para serem fabricados para seus clientes. A Eastop acompanha os avanços na indústria e os adota para garantir a qualidade e eficiência de seus tubos.

A Qingdao Eastop Plastic Products Co. Ltd. dedica-se à fabricação e exportação de mangueiras de borracha e plástico. Os principais produtos que oferecemos são mangueiras industriais de PVC, tubos flexíveis reforçados, acoplamentos e braçadeiras para mangueiras, adequados para o transporte de diversos meios, como ar, água, óleo, gás, pó, grânulos etc. Amplamente utilizados nas indústrias de mineração, agricultura, mineração e construção. Somos capazes de atender às necessidades de diferentes clientes.

impressionante instalação de fabricação de 62 000 metros quadrados possui 20 oficinas especiais que demonstram o compromisso com a produção produtiva capaz de atender às demandas dos clientes em tubos flexíveis reforçados, mantendo altos padrões de qualidade; 300 linhas de produção e uma equipe composta por 230 funcionários altamente qualificados desempenham um papel crucial no trabalho, garantindo que cada linha de produto cumpra rigorosas especificações da empresa

O tubo flexível reforçado ISO é um testemunho do sistema de gestão da qualidade que implementamos e do nosso compromisso com a melhoria contínua. Tornamo-nos agora um dos principais fornecedores da China de mangueiras, com uma capacidade de produção de 30 000 toneladas. Isto é uma prova do nosso compromisso com a excelência, pois entregamos produtos que consistentemente atendem aos padrões do setor. Estamos focados em garantir a satisfação dos nossos clientes e a inovação é a força motriz por trás do nosso sucesso. Também mantemos fortes relações com os nossos clientes, estabelecendo-nos como um parceiro comercial confiável.

Nossa fábrica adotou as mais recentes tecnologias e equipamentos, reforçando tubos flexíveis de matérias-primas e processos de fabricação; sempre fornecemos produtos de alta qualidade e garantimos a durabilidade dos nossos produtos. Nossos produtos atendem aos padrões Reach, RoHS, PAHS, etc. Já atendemos mais de 500 clientes em mais de 80 países, incluindo o Reino Unido, Estados Unidos da América, Canadá, Austrália e Brasil.